Process Monitoring Loggers

Data Loggers with Universal Multi-Input capabilities found in all sorts of applications.

Display

per page

Monnit Enterprise Dry Contact Wireless Sensor

Detect if contact is made or broken between two wired points.

$285.00 (ex gst)

Monnit Industrial Dry Contact Wireless Sensor

Detect if contact is made or broken between two wired points. Be alerted via email, text, or call if a contact is broken or if the two points make contact when they shouldn’t be.

$517.00 (ex gst)

Monnit Enterprise Motion Detection Wireless Sensor

Monitor movement by people or animals in virtually any area or facility within a range of up to 15 feet

$335.00 (ex gst)

Monnit Enterprise Motion, Humidity & Temp Wireless Sensor

A three-in-one Wireless Motion+ Sensor combines the power of monitoring people’s movement, ambient temperature, and relative humidity

from $519.00 (ex gst)

Monnit Enterprise Tilt Wireless Sensor

Better understand your operations, machine health, or structure status by collecting inclination data or tracking pitch and roll with Monnit’s Enterprise Tilt Sensors.

$322.00 (ex gst)

Monnit Industrial Tilt Detection Wireless Sensor

Monnit’s Wireless Tilt Detection Sensor tracks the position (pitch) of access barriers, heavy equipment arms, and crucial machinery.

$531.00 (ex gst)

Monnit Industrial Tilt Wireless Sensor

Collecting inclination data or tracking pitch and roll with Monnit’s Enterprise Tilt Wireless Sensors to better understand operations and machine health

$532.00 (ex gst)

Monnit Enterprise G-Force Snapshot Wireless Accelerometer

Monnit’s Wireless G-Force Snapshot Sensor activates at a user-set time to measure acceleration on the X, Y, and Z axes to determine G-force. This digital, low-power sensor’s applications include tracking machine inclination or tilt, detecting asset orientation, or testing for vibrations.

$322.00 (ex gst)

Monnit Industrial G-Force Snapshot Wireless Accelerometer

Monnit’s Wireless G-Force Snapshot Sensor activates at a user-set time to measure acceleration on the X, Y, and Z axes to determine G-force. This digital, low-power sensor’s applications include tracking machine inclination or tilt, detecting asset orientation, or testing for vibrations

$532.00 (ex gst)

Monnit Enterprise Activity Detection Wireless Sensor

The Activity Sensors can be used in a host of applications where detecting vibration (sudden movement) or counting the number of vibrations is required.

$347.00 (ex gst)

Monnit Industrial Activity Detection Wireless Sensor

The Activity Detection sensors detects sudden movements, or non-movement of a given device or surface and alerts you of the change.

$581.00 (ex gst)

Monnit Enterprise AC-DC Voltage Wireless Sensor

This sensor allows you to remotely monitor potential differences (voltage) between two electrical points. If voltage deviates from your pre-set limits, you’re alerted by email, text, or call.

from $458.00 (ex gst)

Monnit Enterprise Voltage Detection Wireless Sensor

The 0–200 VDC and 0–500 VAC devices are triggered by electricity’s presence or absence in batteries or other sources, such as solar equipment.

from $458.00 (ex gst)

Monnit Industrial Voltage Detection Wireless Sensor

Machine operators and facility managers have a second set of eyes in Monnit’s Voltage Detection Wireless Sensors. This wireless voltage sensor tracks power sources or monitors the on/off status of equipment and machines, as well as battery levels.

from $569.00 (ex gst)

Monnit Industrial Voltage Wireless Meter

Monnit’s 0–200 VDC or 0–500 VAC sensors measure the voltage between two electrical points, such as batteries or other sensors and measure the reported voltage.

from $556.00 (ex gst)

Monnit Enterprise Button Press Wireless Sensor

Upon pressing the sensor’s button, a notification is sent to iMonnit software. An on-sensor LED confirms software response, and an alert is issued via text, email, or call.

$335.00 (ex gst)

Monnit Enterprise Ultrasonic Level Wireless Sensor

Monnit’s Ultrasonic Sensors can be used in various applications to measure distances between the sensor and objects in its path. These sensors are impervious to target surface and colour and feature autocalibration algorithms which allow them to adapt to variable environmental conditions and compensate for temperature and humidity effects.

$606.00 (ex gst)

Monnit Industrial Ultrasonic Wireless Sensor

Monnit’s Industrial Ultrasonic Sensors can be used in various applications to measure distances between the sensor and objects in its path.

$1,853.00 (ex gst)

Monnit Industrial Three-Phase Current Wireless Meter

The Industrial Wireless Three Phase Current Meter (20A, 150A & 500A) measures the RMS current of an alternating current (AC) system using 3 current transducers (CTs) that wrap around the wires of a three-phase power system.

from $1,372.00 (ex gst)

Monnit Enterprise Air Particulate Wireless Meter

This mount-and-monitor device measures Particulate Matter that’s coarse (PM10), fine (PM2.5), and ultrafine (PM1) inside mines, production facilities, commercial kitchens and facilities, as well as business buildings.

$903.00 (ex gst)

Monnit Enterprise Air Velocity/Speed Wireless Sensor

This sensor measures the pressure difference between its two ports, accounts for ambient temperature and altitude, and determines system airflow speed in meters per second (m/s).

$1,188.00 (ex gst)

Monnit Industrial Air Velocity/Speed Wireless Sensor

This air velocity/speed sensor measures the pressure difference between its two ports, accounts for ambient temperature and altitude, and determines system airflow speed in meters per second (m/s).

$1,360.00 (ex gst)

Monnit Enterprise Differential Air Pressure Wireless Sensor

This sensor measures the pressure difference between two input ports and transmits the measurement to iMonnit from -500 Pa to 500 Pa

$915.00 (ex gst)

Monnit Industrial Differential Air Pressure Wireless Sensor

Measure the pressure difference between two input ports and transmits the measurement to iMonnit from -500 Pa to 500 Pa

$1,013.00 (ex gst)

Monnit Enterprise Carbon Dioxide (CO2) Wireless Sensor

This sensor monitors Carbon Dioxide (CO2) gas; if levels exceed preset limits, designated personnel are alerted via text, email, or call

$915.00 (ex gst)

Monnit Enterprise Pressure Wireless Sensor

Monnit’s Industrial Wireless Pressure Meter monitors gas, liquid, or vapor supply lines.

from $1,149.00 (ex gst)

Monnit Industrial Pressure Wireless Sensor

Monnit’s Industrial Wireless Pressure Meter monitors gas, liquid, or vapor supply lines

from $1,248.00 (ex gst)

Monnit Enterprise Carbon Monoxide (CO) Wireless Sensor

Measure the amount of CO gas in the surrounding air and receive real time alerts if levels have been exceeded

$680.00 (ex gst)

Monnit Enterprise Hydrogen Sulfide (H2S) Gas Wireless Sensor

Measure the levels of toxic H2S gas in the environment and get alerts when thresholds are breached

$680.00 (ex gst)

Monnit Industrial Propane Tank Level Wireless Monitor

This sensor installs quickly, allowing propane providers to remotely monitor tank levels.

$903.00 (ex gst)

Monnit Industrial Resistance Wireless Sensor

The Wireless Resistance Sensors reads the resistance across any resistive load and reports back the measured resistance.

$532.00 (ex gst)

Monnit Enterprise Resistance Wireless Sensor

Monnit’s Industrial Resistance Sensor reads the resistance across any resistive load and reports back the measured resistance.

$409.00 (ex gst)

Monnit Industrial IoT Gateway

The ALTA® by Monnit Wireless IoT Gateway combines a 4G LTE CAT-M1/NB2 cellular engine with Monnit’s wireless access point network to aggregate and communicate data from Monnit ALTA Wireless Sensors.

$1,304.00 (ex gst)

Monnit IoT Gateway (4G)

The ALTA® by Monnit Wireless IoT Gateway combines a 4G LTE CAT-M1/NB2 cellular engine and Ethernet platform (commercial only) with Monnit’s wireless access point network to aggregate and communicate data from Monnit ALTA Wireless Sensors.

$958.00 (ex gst)

Monnit Ethernet Gateway

The MonnitLink Ethernet gateway allows your Monnit Wireless Sensors to communicate with the iMonnit™ Online Wireless Sensor Monitoring and Notification System without the need for a PC

$613.00 (ex gst)

Monnit ALTA Serial MODBUS Gateway

The ALTA Serial MODBUS Gateway is used for connecting a wireless sensor network to a PLC SCADA System.

$759.00 (ex gst)

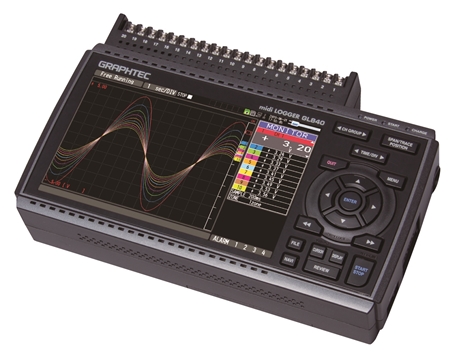

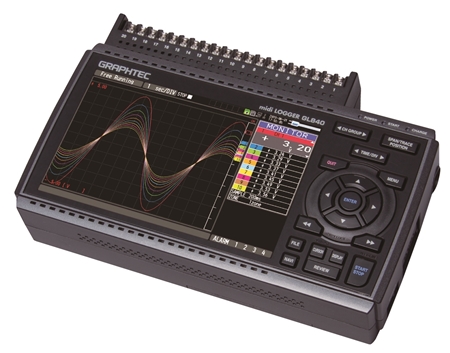

Graphtec GL840-M - 20 Channel Data Logger

The Graphtec GL840-M with 20 Channels expandable to 200 isolated channels with multifunction input

call for pricing

Graphtec GL840-WV - 20 Channel Data Logger

The Graphtec GL840-WV with 20 Channels expandable to 200 isolated channels with multifunction input and High Voltage

call for pricing

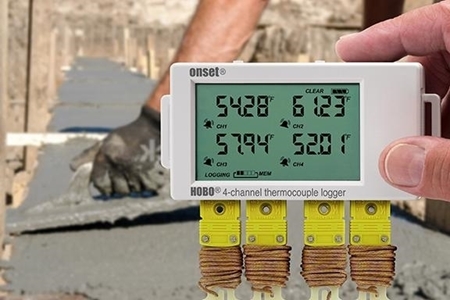

HOBO Fumigation Temperature Data Logging Kit

New Australian regulations require temperature data logging and record-keeping of fumigation processes. This kit includes a four-channel Bluetooth data logger in a waterproof enclosure and four temperature sensors.

$1,085.00 (ex gst)

HOBO Concrete Curing Temperature Data Logger Kit

The Concrete curing temperature data logger kit includes everything you need to start logging the temperature curing process of concrete.

$0.00 (ex gst)